Parts Of A Truck Body: A Comprehensive Guide to Understanding Your Vehicle’s Anatomy types.truckstrend.com

Trucks are the workhorses of the modern world, indispensable for transportation, construction, logistics, and countless other industries. From heavy-duty haulers to nimble utility vehicles, each truck is a complex marvel of engineering designed for specific tasks. While the engine and drivetrain provide the power, it’s the truck body that defines its function, capacity, and overall utility. Understanding the various parts of a truck body isn’t just for mechanics; it’s crucial for owners, operators, and fleet managers to ensure safety, optimize performance, extend vehicle lifespan, and make informed decisions regarding maintenance and upgrades.

This comprehensive guide will dissect the anatomy of a truck body, exploring its essential components, their functions, types, and important considerations for their care and maintenance.

Parts Of A Truck Body: A Comprehensive Guide to Understanding Your Vehicle’s Anatomy

1. The Cab: The Command Center and Driver’s Sanctuary

The cab is the control hub of any truck, housing the driver and, in some cases, a crew. It’s where all operational controls are located and where the driver spends countless hours, making comfort, safety, and ergonomics paramount.

-

Key Components:

- Dashboard and Controls: Houses the instrument cluster (speedometer, tachometer, fuel gauge, etc.), warning lights, infotainment system, climate controls, and various switches for lights, wipers, and specialized equipment.

- Seating: Designed for long-haul comfort, often featuring air suspension, multiple adjustments, and lumbar support to reduce driver fatigue.

- Steering Wheel and Pedals: Essential for vehicle control. Many modern trucks feature multi-function steering wheels with integrated controls.

- Doors and Windows: Provide entry/exit and visibility. Power windows and mirrors are standard.

- Windshield and Mirrors: Crucial for visibility. Windshields are often large for maximum forward vision, and side mirrors (including convex mirrors) provide comprehensive views of the truck’s surroundings.

- Safety Features: Airbags, seatbelts, collision avoidance systems, lane departure warnings, and advanced driver-assistance systems (ADAS) are increasingly integrated.

-

Types of Cabs:

- Day Cab: Designed for daily operations, without a sleeping compartment. Common in local delivery or construction trucks.

- Sleeper Cab: Features a built-in sleeping area behind the seats, ranging from basic bunks to elaborate living spaces with amenities, ideal for long-haul trucking.

- Crew Cab (Extended Cab): Offers additional seating capacity behind the front seats, suitable for work crews.

-

Important Considerations: Ergonomics play a huge role in driver productivity and safety. Good visibility, intuitive controls, and a comfortable environment reduce stress and fatigue. Regular cleaning, checking window mechanisms, and ensuring all dashboard lights and gauges are functional are key maintenance tasks.

2. The Chassis: The Backbone of Strength and Stability

Often referred to as the "frame," the chassis is the foundational structure of the truck, to which all other components – including the engine, drivetrain, cab, and cargo body – are attached. It provides the strength and rigidity needed to support heavy loads and withstand the stresses of the road.

-

Key Components:

- Frame Rails: The long, parallel beams (usually C-channel or box-section steel) that run the length of the truck, forming the primary load-bearing structure.

- Crossmembers: Horizontal beams that connect the frame rails, adding torsional rigidity and providing mounting points for various components.

- Axles: Support the weight of the truck and its cargo, transferring power to the wheels. Trucks typically have multiple axles (front steer axle, rear drive axles, sometimes tag or pusher axles).

- Suspension System: Comprising springs (leaf springs, coil springs, or air springs) and shock absorbers, the suspension system cushions the ride, absorbs road irregularities, and maintains tire contact with the road.

- Braking System: Essential for safety, truck brakes are typically air-actuated systems (air brakes) with drum or disc brakes on each wheel. Anti-lock Braking Systems (ABS) are standard.

- Steering System: Connects the steering wheel to the front wheels, allowing the driver to control the truck’s direction. Power steering is universal in modern trucks.

- Wheels and Tires: Directly support the truck’s weight and provide traction. Proper tire selection and maintenance (pressure, rotation, alignment) are critical for safety, fuel efficiency, and longevity.

-

Importance: The chassis is paramount for the truck’s structural integrity, load-carrying capacity, handling, and stability. A robust chassis ensures the vehicle can safely transport its intended cargo over varied terrains.

-

Maintenance Tips: Regular inspection for cracks, bends, or corrosion on the frame rails and crossmembers is vital. Lubrication of suspension components, checking brake lines and air tanks, and ensuring proper wheel alignment are ongoing tasks. Rust prevention, especially in harsh climates, is crucial for chassis longevity.

3. The Body/Cargo Area: The Workhorse Tailored for the Task

The cargo area is the section specifically designed to carry goods, equipment, or specialized payloads. Its design varies dramatically depending on the truck’s primary function.

-

Types and Features:

- Flatbed Body: A simple, open platform with no sides or roof, ideal for transporting oversized or irregularly shaped cargo that can be secured with straps or chains. Offers maximum flexibility but no weather protection.

- Considerations: Load securement points (D-rings, rub rails), material (steel, aluminum), bed length and width.

- Box/Dry Van Body: An enclosed, rectangular box, typically made of aluminum or fiberglass-reinforced plywood (FRP). Protects cargo from weather and theft. Common for general freight, parcel delivery, and moving services.

- Considerations: Rear roll-up or swing doors, interior lighting, tie-down rails (E-track), insulation (if required).

- Refrigerated (Reefer) Body: A specialized insulated box body equipped with a refrigeration unit to maintain a specific temperature range. Essential for transporting perishable goods like food, pharmaceuticals, and flowers.

- Considerations: Insulation R-value, refrigeration unit capacity, temperature monitoring systems, internal air circulation.

- Dump Body: Features a large, open-top container that can be hydraulically lifted to dump bulk materials (sand, gravel, dirt, asphalt). Common in construction and mining.

- Considerations: Material (heavy-duty steel or aluminum), capacity (cubic yards), hoist mechanism, tailgate design (barn door, high-lift).

- Tanker Body: Cylindrical or elliptical tanks designed to transport liquids (water, fuel, chemicals) or gases. Built with specific materials and safety features depending on the substance.

- Considerations: Material compatibility, baffling (to prevent sloshing), pressure relief valves, specialized loading/unloading systems.

- Stake Body: Similar to a flatbed but with removable or fixed wooden/metal stakes around the perimeter, allowing for higher cargo stacking while maintaining easy access.

- Considerations: Stake height, material strength, ease of stake removal.

- Service/Utility Body: Features multiple external compartments and often a large central cargo area. Designed for tradespeople to carry tools, equipment, and parts securely and organized.

- Considerations: Compartment size and security, shelving options, ladder racks, crane mounts (for heavy equipment).

- Roll-off Container System: A truck chassis equipped with a hydraulic system that can pick up, transport, and drop off large waste containers (dumpsters).

- Flatbed Body: A simple, open platform with no sides or roof, ideal for transporting oversized or irregularly shaped cargo that can be secured with straps or chains. Offers maximum flexibility but no weather protection.

-

Maintenance Tips: Regular cleaning is essential for all cargo bodies. For enclosed bodies, check seals on doors for water leaks. For dump bodies, lubricate hydraulic cylinders and inspect the body for cracks. Tankers require specific cleaning and inspection protocols based on the materials they transport. Load distribution and securement are critical for preventing damage to the body and ensuring safe transport.

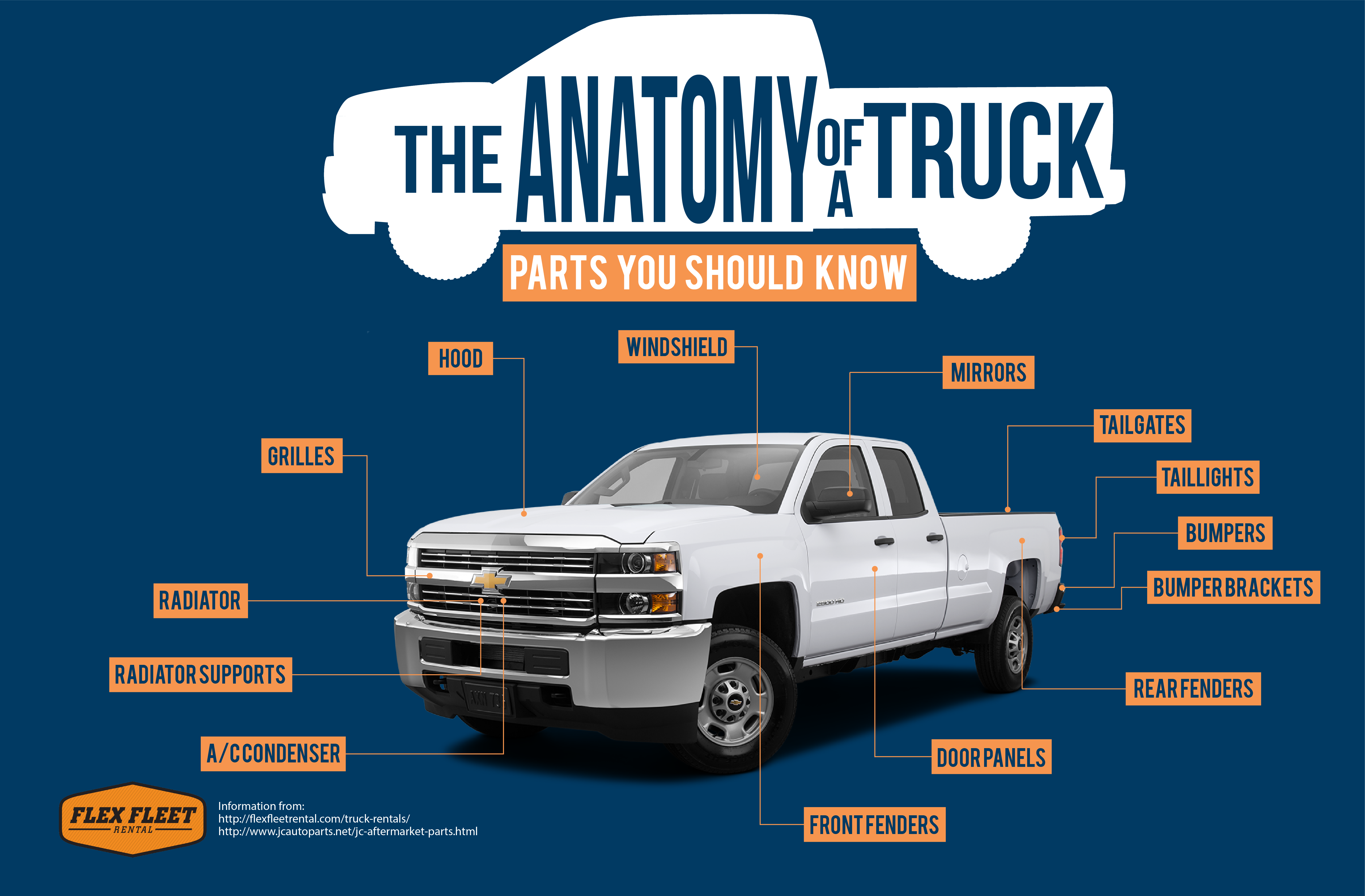

4. External Components & Accessories: Enhancing Function, Safety, and Aesthetics

Beyond the core structural elements, numerous external parts contribute to a truck’s functionality, safety, aerodynamics, and overall appearance.

-

Key Components:

- Bumpers: Front and rear bumpers protect the truck from minor impacts. Heavy-duty trucks often have robust steel bumpers.

- Grille: Located at the front, the grille allows airflow to the engine’s radiator while also serving as a styling element.

- Headlights, Taillights, and Marker Lights: Essential for visibility and signaling, adhering to strict regulatory requirements. LED lighting is increasingly common for its durability and efficiency.

- Mirrors: Side mirrors (often heated and power-adjustable) and sometimes fender-mounted mirrors provide critical rear and side visibility.

- Mud Flaps/Splash Guards: Prevent road spray, rocks, and debris from being thrown up by the tires, protecting other vehicles and the truck itself.

- Running Boards/Steps: Provide easier access to the cab, especially for taller trucks.

- Toolboxes and Storage Compartments: Often mounted on the frame rails or within service bodies, providing secure storage for tools and equipment.

- Aerodynamic Fairings: Side skirts, roof fairings, and gap reducers between the cab and trailer improve airflow, reducing drag and improving fuel efficiency.

- Fuel Tanks: Large-capacity tanks, often dual-mounted, providing extensive range.

- Exhaust System: Directs engine exhaust away from the vehicle and includes components like mufflers and catalytic converters to reduce noise and emissions.

-

Tips: Regularly check all lights for functionality. Keep mirrors clean and properly adjusted. Inspect mud flaps for damage. Ensure fuel caps are secure. Regular cleaning of the exterior not only maintains appearance but also helps identify potential issues like rust or loose components early.

Challenges and Solutions in Truck Body Maintenance

- Rust and Corrosion: Common in areas exposed to road salt, moisture, or chemicals.

- Solution: Regular washing, applying rust-inhibiting coatings, prompt repair of paint chips or scratches, and using galvanized or aluminum components where possible.

- Wear and Tear: Constant vibration, heavy loads, and impact can lead to cracks, dents, and component fatigue.

- Solution: Regular inspections, timely repairs (welding, panel replacement), and using high-quality replacement parts.

- Load-Specific Damage: Improper loading, shifting cargo, or overloading can damage the cargo body.

- Solution: Adhering to weight limits, proper load distribution, using appropriate tie-downs and securement methods, and operator training.

- Electrical Issues: Wiring in the body can be exposed to elements, leading to shorts or malfunctions.

- Solution: Regular inspection of wiring harnesses, ensuring proper insulation, and using waterproof connectors.

- Hydraulic System Failures (for dump/tanker bodies): Leaks, pump failures, or cylinder issues.

- Solution: Regular checks of hydraulic fluid levels, hose integrity, and professional servicing of pumps and cylinders.

Estimated Price Table for Common Truck Body Parts (Illustrative)

Please note that these prices are highly estimated ranges and can vary significantly based on the truck’s make, model, year, part quality (OEM vs. aftermarket), material, supplier, labor costs for installation, and market fluctuations. This table is for general guidance only.

| Part Category | Example Parts Included | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Cab Components | Door shell, Windshield, Seat assembly, Dashboard | $500 – $10,000+ | Varies greatly by size, features (power, heated), and type (day cab vs. sleeper interior). Full cab replacement is significantly higher. |

| Chassis Components | Frame rail section, Axle assembly, Leaf spring, Air bag | $200 – $5,000+ | Depends on specific part, material, and whether it’s a complete assembly or individual component. Frame repairs can be very costly. |

| Cargo Body (Type) | Flatbed (8ft), Dry Van (20ft), Dump Body (10yd) | $3,000 – $50,000+ | Price depends heavily on size, material (steel/aluminum), features (liftgate, refrigeration unit), and complexity. New custom builds are at the higher end. |

| External Components | Headlight assembly, Bumper, Grille, Mud flap, Side mirror | $50 – $1,500+ | Individual parts like a mud flap are cheap; full headlight assemblies or heavy-duty custom bumpers are more expensive. |

| Aerodynamic Kits | Side skirts, Roof fairing, Gap reducers | $1,000 – $5,000+ | Often sold as kits. Benefits in fuel savings can outweigh the initial cost over time. |

| Accessories | Toolbox, Ladder rack, Winch mount, Auxiliary lighting | $100 – $3,000+ | Varies widely based on size, material, brand, and complexity. |

Disclaimer: These are rough estimates for individual components or common body types. A complete, custom-built truck body could cost tens of thousands to over a hundred thousand dollars depending on specialization.

Frequently Asked Questions (FAQ) about Truck Body Parts

Q1: How often should I inspect my truck’s body parts?

A1: A quick visual inspection should be done daily or before each shift (pre-trip inspection). A more thorough inspection, including checking for rust, loose bolts, and proper functionality of lights and doors, should be part of your routine maintenance schedule, typically every few months or during scheduled service intervals.

Q2: What’s the difference between OEM and aftermarket truck body parts?

A2: OEM (Original Equipment Manufacturer) parts are made by the original company that manufactured your truck or the part itself. They generally guarantee fit and quality but are often more expensive. Aftermarket parts are produced by companies other than the original manufacturer. They can be more affordable and sometimes offer performance enhancements, but quality and fit can vary.

Q3: Can I customize my truck’s body?

A3: Absolutely! Many truck owners and businesses customize their truck bodies to suit specific needs, enhance aesthetics, or improve functionality. This can range from adding toolboxes and ladder racks to installing custom flatbeds, service bodies, or even specialized cargo solutions. However, always ensure customizations comply with local regulations and weight limits.

Q4: How important is aerodynamics for a truck body?

A4: Extremely important, especially for long-haul trucks. Aerodynamic fairings (like side skirts and roof fairings) can significantly reduce air resistance, leading to substantial fuel savings over time. Even small improvements in aerodynamics can translate to considerable cost reductions for large fleets.

Q5: What are the biggest challenges in maintaining a truck body?

A5: The biggest challenges include combating rust and corrosion (especially in areas with harsh weather or road salt), managing wear and tear from constant use and heavy loads, and addressing damage from accidents or improper loading. Regular preventive maintenance and prompt repairs are key to overcoming these challenges.

Q6: What’s the lifespan of a typical truck body?

A6: The lifespan of a truck body varies greatly depending on its type, material, usage, and maintenance. A well-maintained steel dump body used heavily might last 10-15 years, while a meticulously cared-for aluminum dry van could last 20 years or more. Proper maintenance and avoiding overloading are crucial for extending lifespan.

Conclusion: The Sum of Its Robust Parts

The truck body is far more than just a shell; it’s a meticulously engineered system of interconnected components, each playing a vital role in the vehicle’s overall performance, safety, and operational efficiency. From the driver’s command center in the cab to the load-bearing strength of the chassis and the specialized functionality of the cargo area, every part contributes to making a truck the versatile and resilient machine it is.

Understanding these components empowers truck owners and operators to make informed decisions about purchasing, maintenance, and upgrades. By prioritizing regular inspections, adhering to maintenance schedules, and addressing issues promptly, you can ensure your truck body remains robust, reliable, and ready to tackle any task for years to come, securing your investment and maximizing your operational uptime.